Company

MKV wins award

Pioneering achievement in recycling - Award ceremony at the K Trade Show 2025

Award Ceremony

The location: the K trade show in Düsseldorf. The date: October 8, 2025. In Hall 7a at the TecPart e.V. booth, the 20th TecPart Innovation Award was presented. Companies were honored for outstanding technical plastic products in the categories of injection molded parts, thermoformed parts, and for the first time in the category of sustainability.

The winner in the sustainability category was the project consortium consisting of Bosch Power Tools (PT), MKV, and HolyPoly.

The award went to the UniversalImpact 800 Closed Loop Edition impact drill from Bosch PT. A unique achievement that represents pioneering work.

The story behind it shows how determination and teamwork can push the boundaries of what is possible.

The Beginning

In the fall of 2021, still during the height of the Corona pandemic, Kai Zies, Managing Director of MKV, thought it was a shame that the high-quality plastic used in power tools was simply being wasted at the end of its life cycle.

MKV, a leader in the mechanical recycling of engineering plastic waste and the production of compounds based on recycled materials, is strong in the field of polyamides. As a supplier to the electrical and electronics industry, the focus was on the potential for polyamide 6 (PA 6) – post-consumer recycled (PCR) PA6 – contained in power tools.

After all, the majority of plastics from WEEE (Waste Electrical and Electronic Equipment) end up being incinerated. This potential for polyamide 6 and the increasingly intense discussions and inquiries surrounding post-consumer recycling (PCR), and recyclates originating from post-consumer sources, fueled the idea of recycling plastics from the WEEE material stream. PCR material was and still is scarce in the field of engineering plastics. Reliable, consistent PCR sources are rare. Recycled polyamide has so far only been reliably available from post-industrial recycling (PIR) and mainly in black. PCR polyamide would therefore fill a gap in the market.

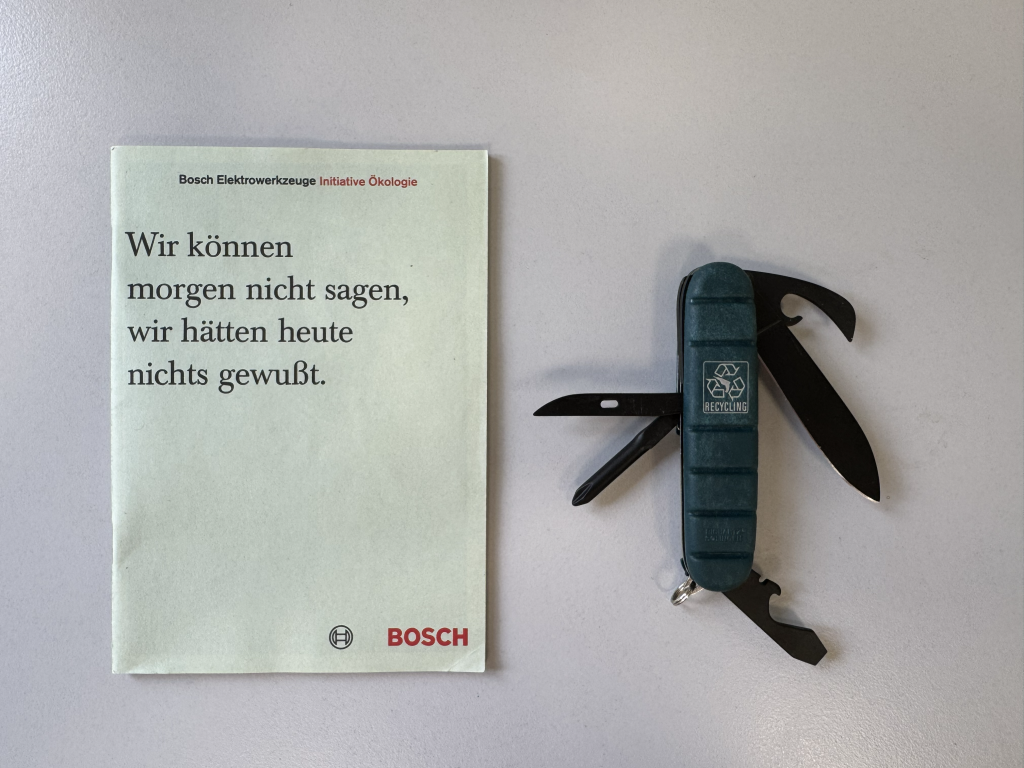

The final trigger was a Swiss Army knife – the only remaining artifact from a long-forgotten project from over 20 years ago. Even back then, Bosch was addressing the issue of "end of product life cycle." The casing of this pocket knife was made from recycled casings of power tools. The documents and results of that project are lost.

How can this potential be harnessed and the material stream from WEEE be tapped into? With this question, Kai Zies turned to Fridolin Pflüger and the HolyPoly team. It was clear that support was needed. This is how the #Powermining project was launched.

Pipe dream or can this work?

The next step was to conduct market research to find out whether post-consumer power tools could be tapped as a new source of engineering plastic waste. The aim was to gain a precise understanding of the challenge and possible starting points in the material flow and how the dismantling and separation of engineering plastics can work.

How does current WEEE recycling work? It turned out that the plastics contained in current WEEE recycling (primarily PA6 & PC-ABS) are treated as contaminants and, due to their small quantity in relation to the overall electrical waste stream, are not positively sorted out and therefore not recycled to a high standard.

Various recycling processes were considered, and the most promising one was selected, along whose process steps research was conducted. Experts were consulted and on-site visits were carried out.

Much was quickly learned about the construction of power tools; which types of plastic are present in addition to polyamide 6 and what their proportion is, but also which joining techniques are used. Is recycling feasible with a partially or fully automated process? The state-of-the-art separation methods were also examined, for example, to address the particular risk of halogenated flame retardants and heavy metals such as cadmium, lead, or mercury in old appliances. They jeopardize the successful recycling process because they can contaminate an entire batch.

What are the material flows? Here, information from Stiftung ear in category 5 – small appliances – was particularly helpful. The next step was to clarify: How can such small appliances with engineering plastics, especially power tools, be isolated and separated in order to optimize the material flow and achieve a critical mass?

Many important insights were gathered, from production and use to dismantling and pollutant testing. In a joint priorities workshop between MKV and HolyPoly in March 2022 at the HolyPoly HQ in Dresden, a number of critical assumptions were subsequently made, which were to serve as hypotheses for validating the detailed recycling process within the framework of a prototype phase. There was no guarantee of success, but the conclusion drawn from the results gathered up to that point was: Let's give it a try!

Project Entry OEM – Bosch Power Tools (PT) comes on board

Even during the priorities workshop, the idea was to ideally win an OEM for the #Powermining project.

In August 2022, the time had come, and Bosch PT was successfully brought on board for the project, and since then, the topic has been driven forward in a three-way collaboration under the leadership of Bosch PT.

The priorities workshop was followed by the feasibility study and potential analysis. The objective quickly evolved and was taken to the next level. The result was no longer just to be a PCR PA 6, but a PA 6 in Bosch Green, in a material quality that would allow the first closed-loop power tool to be launched on the market in 2025. Closed-loop recycling is the supreme discipline of recycling, meaning that the material can be recovered in such high quality that it can be reused for the same or an equivalent application. Such a result in the field of power tools would catapult Bosch PT into a leading global position in the circular economy!

The large-scale feasibility study explored the economic and technical feasibility of a separate material recovery path for technical plastics from end-of-life devices much more extensively than the previous pilot project.

In addition to testing various separation and sorting processes and checking several material batches for their properties such as brand color, impact strength, or tensile strength, extensive data was collected to confirm or refute the previously established hypotheses.

Further interviews were conducted with experts and hands-on tests were carried out, examining thousands of tools and recording a large number of data points. This was very important, as there are significant differences between tool types, brands (Bosch, Makita, Hilti, DeWalt, etc.), and between years of manufacture.

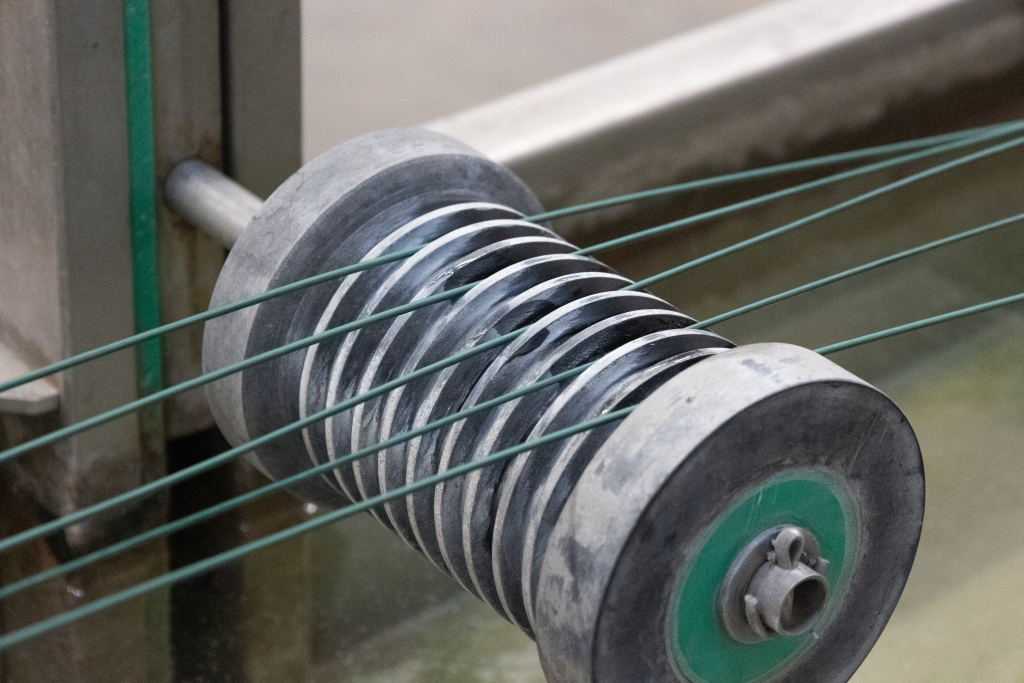

In addition, a general, representative data collection on the end-of-life reality in Germany was compiled. Only with a thorough understanding of the collection and processing of small electrical appliances, and the interplay between initial processors, municipal collection points (e.g., recycling centers), and direct collection from retailers, can the question of sourcing for power tools be answered: how do we obtain the power tools? This is an essential question, without which all subsequent steps, such as identification, shredding, cleaning, fine sorting, pollutant testing, compounding, and injection molding, cannot function. Part of the feasibility study naturally also included the production of several tons of recycled material. MKV handled the manufacturing and analysis in its in-house laboratory at its Beselich location. In addition to black and green, other colors were also produced and tested. Ensuring clear process control was always crucial to achieving the best possible quality in the end product.

The Result – Housing made from 78% Recycled Material

The team from Bosch PT, HolyPoly, and MKV complemented each other perfectly and, thanks to their comprehensive expertise, managed to produce an output material in the form of recycled plastic that meets the same quality requirements despite contamination (firmly adhering substances such as concrete, paint, adhesive tape, etc.) and degradation from the usage phase and recycling process:

- Mechanical properties

- REACH and RoHS compliance

- Processing and application in the series production line

- Existing material and product tests

- Brand color (Bosch Green)

This made it possible to return the recovered plastic to the same application and achieve the project goal!

The housing of the UniversalImpact 800 Closed Loop Edition impact drill is made of 78% recycled plastic. The housing in Bosch green and the black handle are made from 100% recycled plastic. Replacing virgin plastics with mechanically recycled alternatives saves significant amounts of emissions. New PA6-GF has one of the highest CO2 footprints among technical plastics: reductions of 90% and more are possible. The 22% of plastic that is not recycled is found in components such as switches, drill chucks, and soft grips. These are made of different types of plastic or were colored differently.

The project result is unique and anything but a matter of course. The project broke new ground. There was no experience or results to draw upon. Only a pocket knife served as a reminder that it had been tried before, but it was a vision that was ahead of its time. The entire process was monitored and certified by TÜV SÜD.

In view of further regulations at the European level, it is more important than ever to exercise foresight with regard to recycled materials and to secure supply chains and material supply by developing new material streams.

MKV, together with its project partners Bosch PT and HolyPoly, is delighted to receive the TecPart Innovation Award in the sustainability category and hopes for many more accolades for this great project.

The UniversalImpact 800 Closed Loop Edition impact drill will be available in OBI DIY stores from the beginning of November 2025. Kai Zies has already bought the first models, and we will raffle off two of them among the employees of MKV.

Official Bosch press release here.

Official project video on the Bosch PT YouTube channel (in German) here.

Selected LinkedIn posts:

- HolyPoly

- HolyPoly

More news articles can be read here.